LONG TERM STORAGE

PURPOSE AND CONCEPT

AIM

To reduce high maintenance costs and ensure immediate readiness at all times of equipment stored.

CONCEPT

The concept consists of:

Seal hangars off completely on the inside, making the hangars airtight. No air can flow in from the outside and no air can flow out from the inside.

Dehumidifiers are installed to remove the humidity level down to 40% and keep it between 40% – 50% relative humidity 24 hours per day.

This concept is according to NATO specifications.

CORROSION

Outside air consists mainly of two gaseous constituents, dry air and water vapour.

Corrosion is caused when moist air (humidity) comes into contact with metal. Corrosion is the interaction of a metal or alloy with its environment to form chemical compounds.

It is an electrochemical action and requires the presence of moisture and oxygen. Corrosion occurs in the anodic area. In the presence of pollutants such as chlorides the corrosion rate is accelerated

THE CHALLENGE

In order for any equipment, which is in an inactive status, to remain in absolutely perfect condition, the environment in which it is stored is a primary concern. Such an environment needs to be carefully monitored and protected against any potential weathering conditions, and modes of decay, such as corrosion.

An excess or a deficiency of moisture in the air can be a damaging factor, thus it is crucial that the level of moisture in the air is scientifically controlled.

The expected shelf life of unprotected equipment certainly decreases and the materials used in their true construction are rendered useless with time.

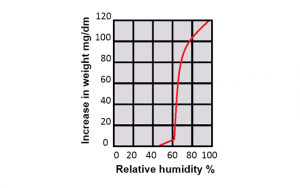

Relative humidity is the term used to describe the amount of moisture present in the air.

On the one hand, too much moisture in the air can lead to corrosion. This occurs when air, at a certain temperature, absorbs too much moisture and when there is a significant drop in temperature the moisture condenses out.

On the other hand, too little moisture in the air causes static electricity as well as causing lubricants to dry out.

The ideal level of relative humidity, conducive the preservation of equipment is between 40% – 50%. This condition is ideal for any item present on a vehicle or airoplane etc.

If the above conditions are maintained, equipment stored will remain in the same condition as long as stored.

THE SOLUTION

By combining the unique sealing techniques of SMB Supplies (PTY) Ltd with the Desiccant Dehumidifiers of MUNTERS from Sweden a perfect environment is created for the long-term storage of equipment.

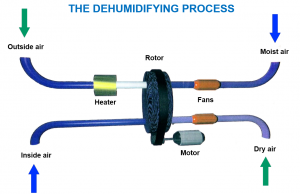

The dehumidifier works in harmony with SMB’s sealant techniques. The dehumidifier wheel comprises tiny channels containing a moisture absorbant material, through which air flows.

The rotor contains a working zone which absorbs moisture from the air while the reactivation zone releases moist air back into the outer atmosphere.

The desiccant wheel dehumidifier can operate at all outdoor temperatures and is effective in both open and closed environments.

SMB Supplies from South Africa offers a global environmental storage control solution.

In addition to the complete installation of the environmental sealant and dehumidifying systems, SMB also offers a complete project management service on the stores.

Thus, if the preservation of any valuable equipment is a high priority, SMB Supplies has the resources, experience and expertise to provide a complete and effective solution

CLADDING MATERIALS

The following cladding materials are used to seal hangars off and make them airtight from the inside:

Polyethylene sheeting – used to cover the walls and ceiling of a hangar. Fitted onto a wooden frame and sealed with COCOON sealant

Advantages are:

Water vapour and air penetrability is practically zero.

Easy to repair after damages

Easy to apply, material is lighter than PVC

Self extinguishing – does not support combustion

Keep the area sand and dust free.

PVC – used to cover all doors and entrances. Used in conjunction with zips and velcro strips for proper sealing. Doors are hoisted and lowered by means of ropes and pullies.

We have a 2 year warrantee on the material and workmanship of the PE and

PVC.

Advantages are:

Water vapour and air penetrability is practically zero.

Easy to repair after damages

Easy to apply, heavy duty material.

Self extinguishing – does not support combustion

Cocoon sealing compound – is used for the sealing of joints, gaps, penetrations, cracks etc. It is a high grade, sprayable chemical, forming a rubber-like stretchable skin.

Advantages are:

Resistance to sea water, sand storms, air pollution, alkalis, oils, greases and most industrial acids.

Self extinguishing – does not support combustion

Resistant to temperatures ranging from –42°C to +85°C

Elasticity up to 250%

Jointless application

Compatible with all building construction materials used.

UV Resistant

Skin is protected against damp, mould and chemical influences

Easily repaired

10 Years warranty

MUNTERS MX DEHUMIDIFIER

Using the MUNTERS MX dehumidifier presents the simplest way to protect equipment from the destructive effects of high humidity.

The simplest way to replace humid air with dry air is to dehumidify it. The simplest way to dehumidify air is with a MUNTERS MED dehumidifier.

The dehumidifier automatically maintains the level of humidity between 40% – 50% relative humidity (RH) ensuring that the equipment remains rust-, corrosion- and damp free whilst stored in an airtight controlled environment.

By using the SMB storing technique significant savings can be achieved in the maintenance costs of equipment over the long term. The lifespan of the equipment stored is also increased

MAINTENANCE OF DEHUMIDIFIERS

Dehumidifier maintenance procedures required that pre-filters must be cleaned with compressed air every second week.

Filters must be replaced every three months and the dehumidifiers require a maintenance service every six months. This is a separate contract, we recoment a separate maintenance contract that can run for a few years at a time.

It is advisable to keep the hangar doors closed. This will ensure optimal functioning of the system and keep it clean.

MAJOR REASONS FOR USING MUNTERS DESICCANT DEHUMIDIFIERS

When using Munters Desiccant Dehumidifiers, in any kind of storage facility, the customer will be able to obtain an exact control of the Relative Humidity – RH%, which will give a 100% protection from humidity related problems, such as Corrosion, Mould, Electrical malfunctions.

By creating an airtight construction through Cocooning, Lining and PVC doors, the infiltration of unwanted air is eliminated to high degree. The elimination of infiltration gives a sand and dust free environment, which saves the equipment stored, and it reduces the moisture load into the building most dramatically.

By controlling Relative Humidity and not the Temperature, the energy consumption will be many times lower. A humidity sensor monitoring the Relative Humidity – RH% in the store will control the Desiccant Dehumidifier, which means that the unit will only be in operation when it is required. However, if you need temperature control it can be upgraded.

When using Munters Desiccant Dehumidification Technique, the surface temperature of the stored equipment will always be higher than the Dew Point Temperature of the ambient air. When using other techniques like cooling, the Surface Temperature of the stored equipment will be much lower the Dew Point Temperature of the ambient air, which will lead to condensation on the equipment when taken out, and even when the doors are opened.

The operation/performance of the Desiccant Dehumidification System

In this paragraph we would like to explain the operation/performance sequences based on the ambient conditions and the humidity requirements stipulated as the design condition. In the attached IX-Diagram we have marked some important conditions explained below.

The Ambient Design Condition, used in the United Arab Emirates (115oF Db/90oF Wb) or (46oC Db/32oC Wb) the Moisture Content at this point is 24.5g/kg of air, and the Relative Humidity is RH38%. At this point the Desiccant Dehumidifier will be switched off as the RH is below 40%

At night however, the ambient temperature will be lower and the Relative Humidity will therefore increase, see arrow 1A in IX-Diagram. As one can see the RH% increases, as the Db-Temperature is reduced, new RH% in this example 68%.

When the above occurs the Munters Desiccant Dehumidifier will reduce the moisture content of the air so that 40% RH is obtained at the Db temperature in the store at that specific time. See arrow 2 in IX-Diagram (small temperature increase due to released evaporation energy).

If the ambient temperature remains the same the Munters Desiccant Dehumidifier will automatically be switched on and off keeping the Relative Humidity at 40% + 5%.

In reality we all know that the daytime temperature will increase which will lead to a temperature increase also inside the store. And when this happens the Relative Humidity goes down and therefore the Desiccant Dehumidifier stops, no need for any further dehumidification. See arrow 3 in IX-Diagram.

It can thus be concluded that as the Db temperature goes up and down inside the store the Desiccant Dehumidifier will automatically be switched on and off depending on the dehumidification demand. One thing that we however can determine is that the units never will be in operation when the Db temperature in the store exceeds 40oC or 114oF.

ADVANTAGES OF DEHUMIDIFIERS VS COOLING

The main purpose is to maintain the level of humidity in the hangar between 40%-50% RH in order to avoid condensation. When condensation occurs the Dew Point (DP) temperature of the air is higher than the temperature of the metal surface or electronics of the equipment stored.

If equipment is moved from an air-conditioned environment condensation occurs on the surface of the metal as well as on the components leading to rust and corrosion.

Dehumidifiers can work in a higher temperature band than air conditioners.

Dehumidifiers use a maximum of 25% of the energy of air conditioners

WARRANTY

We have a 2 year warranty on the complete store and 10 years on the Cocoon covering workmanship and material

RECOMMENDATIONS

SMB Supplies highly recommends the installation of a fire alarm warning system as well as the presence of portable fire fighting equipment to be kept ready in every store in order to minimize any potential threat of fire. This fire alarm warning system can be connected to your nearest duty room or fire brigade. The portable trolley, which is filled with an extinguishing agent can be used by the store personel as a frontline extinguisher till the fire brigade shows up.

Furthermore, each store or hangar should contain at least one door for personnel to enter and exit the store – for safety reasons and to prevent hangar doors from being opened and closed unnecessary.